JAY PHARMA EQUIPMENTS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JAY PHARMA EQUIPMENTS

Lotion Mfg Plant

Description / Specification of Lotion Mfg Plant

We are involved in offering a wide range of Lotion Mfg Plant to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Lotion Mfg Plant. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

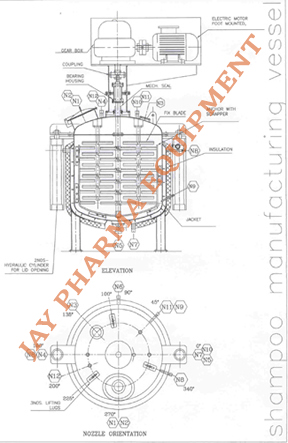

Shampoo Manufacturing Plant

Shampoos are typically viscous liquids, either clear or opaque (pearlised), containing 20–40% solids, adjusted to approximately pH 5.5. Most, but not all, have viscosities in the ratio of 500–1500 centipoise. A hair shampoo may be defined as a detergent specifically formulated for the washing of hair, and packaged in a user-convenient form. Typically, a shampoo must clean well, rinse easily, impart gloss to the hair, minimise tangle and not damage the hair structure, or the scalp or the eyes.

MANUFACTURING PROCESS

Shampoos are manufactured by simple slow blending in a stirred vessel. The vessel may be jacketed for heating. Vessels are normally closed type and subjected to vacuum to avoid excessive foaming when foaming agent is added. For best results contra type rotating stirrer is best used for shampoo manufacturing.

Ingredients are weighed or metered incrementally into the mixing vessel, with thorough mixing between each addition. A moderate amount of heat is used to reduce the viscosity and so facilitate ease of mixing.

Some pearlising agents are waxy solids at ambient temperature and require melting in a premixing vessels before use. Demineralised water is most commonly used in order to minimise contamination of the product.

No further processing is required after blending, & perfuming and the product may be packed off directly from the mixing vessel. Or may be transferred to storage vessels from where they are transferred to the filling machines.

Many companies make the bases for the shampoos where they do all the premxing of surfactants, sles, other ingredients and sell the same to major industries These industries are mainly called the formulators and in this second level processing will involve only the addition of water, colour and fragrance. In case of ayurvedic or herbal shampoos, they add their propriety formulae ingredients themselves so that no one knows the exact nature of ingredients and its details.

Hair Oil Manufacturing Plant

GENERAL

Hair Oil are typically viscous liquids, either clear or opaque. They come in various types from normal hair oils, ayurvedic, herbal, medicinal, etc and cater to different types of hairs.

MANUFACTURING PROCESS

Hair oils is one of the most simplest to manufacturer. Hair oil is manufactured in simple stirring type vessel at slow speed. The different type of oil bases are mixed as per the formulae and then active ingredients are added. Perfuming is done and then directly taken for filling.

VESSELS REQUIRED FOR A SHAMPOO PLANT

Oil Manufacturing Vessel

Manufacturing vessel is cylindrical vessels with dished bottom vessels. Top of the vessel loose lid Agitator assembly in the manufacturing vessel., slow speed Anchor agitator or paddle type agitator. Bottom outlet is provided. No additional gadgets are required for manufacturing hair oil

Storage Vessel

Storage vessel is simple vessel used to store Hair Oils. It is cylindrical type of vessel with dished bottom, loose top lid. Bottom valve is provided with din fittings to facilitate the pipeline connection. Its capacity is the same as the

Talcum Powder Mfg Plant

Description / Specification of Talcum Powder Mfg Plant

We are involved in offering a wide range of Talcum Powder Mfg Plant to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Talcum Powder Mfg Plant. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

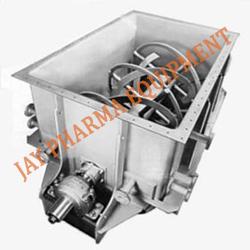

Toothpaste Manufacturing Plant

TOOTHPASTE MANUFACTURING MIXER consists of a Main Manufacturing Vessel also known as Contra Mixer. Contra Mixer as the name suggest works on the principle of Contra rotation of Blades for simultaneous beating and scraping operation. The mixer is highly versatile and mostly used for manufacturing Tooth Paste, Creams, Cosmetics and other viscous products.

The Mixing Assembly consists of series of paddle type blades of appropriate shape to move the material back towards the centre of the container. The paddle type blades are provided on the central shaft which runs through a hollow shaft on which other sets of blades are welded. Both the sets of blades intermeshes with each other and rotates in clockwise and anti-clockwise direction respectively and one sets also scraps the container wall for thorough and uniform mixing of the material.

The mixer is so designed to withstand high vacuum applied during the process for optimum mixing. Contra Mixer is provided with a jacket for cooling or heating as per the application. The vessel shall have a shell of suitable thickness with a hemispherical bottom and flanged top dish made out of S.S. 316 plate. The vessel shall be jacketed with MS jacket ( SS304 jacket provided on extra cost on demand, if required ) of suitable with stiffeners suitable for steam pressure of 4 to 5 Kg/cm2. The jacket shall be insulated with 50 mm thick glass wool insulation and shall be cladded with 16 SWG M.S. or SS304 material. The vessel shall be suitable for 600 to 700 mm of Hg vacuum and internal pressure of 3 Kgs / cm2.

The top lid of the Mixer m/c shall be provided with hydraulic lifting and lowering arrangement, if required. Hydraulic arrangement will consist of : ( Optional at extra cost )

a. Hard Crome plated HYDRAULIC CYLINDERS ( 2 Nos. )

b. Limit switches at upper and lower limits

c. Power pack with direction control valve by actuated

Jar Filling Machine

IMPORTANT SPECIAL FEATURES

- Capability to handle a large range of tube sizes

- Automatic cap tightening

- No-tube-no-fill device

- Automatic tube infeed

- Adjustable filling pump and several optional attachments

- Can handle tube diameters from 10 mm to 40 mm and lengths from 40 mm to 200 mm. ~ Automatic tube infeed with cassette loader.

- Simultaneous accessibility of many tube holders in case of manual infeed.

- Tube cleaning device for dust removal (particularly required for pharmaceutical and~ food products)

- Adjustable filling pump with different volumes:. - Ease in removal of pump components for cleaning and changeover. -Contact parts are corrosion resistant, - No-tube-no-fill device, - Blow off device to cut "Rat tail" of highly viscous products.- Photo-electric tube registration for automatic positioning of tube orientation. - Multiple folding stations for tube closure. - Code marking on the closure with digits and/or letters. -Transportation of filled tubes forward and backward.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.